Project Alumni: Ulrike Thomas (TU Chemnitz)

Supported By: NSF

|

Disassembly sequence planning identifies physically viable plans to disassemble an assembly of parts. It is often used in end-of-life product design to verify the future ability to disassemble the product for recycling or repairs. This field is crucial towards a more automated product design and manufacturing process.

Our initial work used sampling-based motion planning techniques to find valid disassembly sequences by treating each part as a separate movable object or robot. It biased sampling along part face normals and was successful in disassembling several small puzzle-like problems.

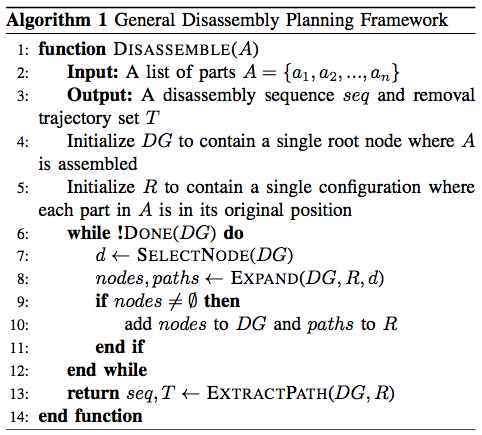

We have more recently developed a general framework for disassembly sequence planning. This framework is capable of allowing different types of search schemes (exhaustive vs. preemptive), various part separation techniques, and the ability to group parts, or not, into subassemblies to improve the solution efficiency and parallelism. This gives the new ability to approach the disassembly sequence planning problem in a truly hierarchical way. We also developed a method for subassembly identification based on collision information.

We use motion planning to generate disassembly sequences. Our approach treats the parts in the assembly as robots and operates in the composite configuration space of all the individual parts. It then searches in this composite configuration space for a valid disassembly sequence using popular sampling-based motion planning techniques.

Although a purely randomized approach to sampling is successful in systems with a small number of parts, typical assemblies consist of numerous parts and the corresponding composite C-spaces have high dimensionality. In addition, a completely randomized sampling approach would be ineffective since many important configurations for the disassembly sequence will involve closely packed parts, i.e., the disassembly sequence will pass through narrow passages in the C-space. Our solution to this problem is to bias the sampling by computing potential movement directions based on the geometric characteristics of configurations known to be reachable from the assembled configuration, such as the face normals of the parts.

Our experimental results with several non-trivial puzzle-like assemblies show the potential of this approach:

We develop a new general framework for disassembly sequence planning. This framework is a flexible method for the complete disassembly of an object; versatile in its nature, allowing different types of search schemes (exhaustive vs. preemptive), various part separation techniques, and the ability to group parts, or not, into subassemblies to improve the solution efficiency and parallelism. This gives the new ability to approach the disassembly sequence planning problem in a truly hierarchical way.

By simply changing the definitions of the framework's subroutines, a wide spectrum of disassembly search strategies may be achieved. We demonstrate two different search strategies using the framework that can either yield a single solution quickly or provide a spectrum of solutions from which an optimal may be selected.

We also develop a method for subassembly identification based on collision information.

Our results show improved performance over an iterative motion planning based method for finding a single solution and greater functionality through hierarchical planning and optimal solution search.

Insights from an Industrial Collaborative Assembly Project: Lessons in Research and Collaboration, Tan Chen, Zhe Huang, James Motes, Junyi Geng, Quang Minh Ta, Holly Dinkel, Hameed Abdul-Rashid, Jessica Myers, Ye-Ji Mun, Wei-che Lin, Yuan-yung Huang, Sizhe Liu, Marco Morales, Nancy M Amato, Katherine Driggs-Campbell, Timothy Bretl, ICRA 2022 WORKSHOP ON COLLABORATIVE ROBOTS AND THE WORK OF THE FUTURE, Philadelphia, PA, USA, May 2022. @article{chen2022insights, Significant progress in robotics reveals new opportunities to advance manufacturing. Next-generation industrial automation will require both integration of distinct robotic technologies and their application to challenging industrial environments. This paper presents lessons from a collaborative assembly project between three academic research groups and an industry partner. The goal of the project is to develop a flexible, safe, and productive manufacturing cell for sub-centimeter precision assembly. Solving this problem in a high-mix, low-volume production line motivates multiple research thrusts in robotics. This work identifies new directions in collaborative robotics for industrial applications and offers insight toward strengthening collaborations between institutions in academia and industry on the development of new technologies.

Keywords: Assembly, Industrial Applications, Interaction

Links : [ArXiv] BibTex

title={Insights from an Industrial Collaborative Assembly Project: Lessons in Research and Collaboration},

author={Chen, Tan and Huang, Zhe and Motes, James and Geng, Junyi and Ta, Quang Minh and Dinkel, Holly and Abdul-Rashid, Hameed and Myers, Jessica and Mun, Ye-Ji and Lin, Wei-che and others},

journal={arXiv preprint arXiv:2205.14340},

year={2022}

}Abstract

A General and Flexible Search Framework for Disassembly Planning, Timothy Ebinger, Sascha Kaden, Shawna Thomas, Robert Andre, Nancy M. Amato, and Ulrike Thomas, In Proc. IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 1-8, Brisbane, Australia, May 2018. DOI: 10.1109/ICRA.2018.8460483 @inproceedings{ebinger2018general, We present a new general framework for disassembly sequence planning. This framework is versatile allowing different types of search schemes (exhaustive vs. preemptive), various part separation techniques, and the ability to group parts, or not, into subassemblies to improve the solution efficiency and parallelism. This enables a truly hierarchical approach to disassembly sequence planning. We demonstrate two different search strategies using this framework that can either yield a single solution quickly or provide a spectrum of solutions from which an optimal may be selected. We also develop a method for subassembly identification based on collision information. Our results show improved performance over an iterative motion planning based method for finding a single solution and greater functionality through hierarchical planning and optimal solution search.

Keywords: Assembly, Sampling-Based Motion Planning

Links : [Published] BibTex

title={A General and Flexible Search Framework for Disassembly Planning},

author={Ebinger, Timothy and Kaden, Sascha and Thomas, Shawna and Andre, Robert and Amato, Nancy M and Thomas, Ulrike},

booktitle={2018 IEEE International Conference on Robotics and Automation (ICRA)},

pages={1--8},

year={2018},

organization={IEEE}

}Abstract

Disassembly Sequencing Using a Motion Planning Approach, Sujay Sundaram, Ian Remmler, Nancy Amato, In Proc. IEEE International Conference on Robotics and Automation (ICRA), Seoul, South Korea, May 2001. DOI: 10.1109/ROBOT.2001.932818 @INPROCEEDINGS{932818, author={S. {Sundaram} and I. {Remmler} and N. M. {Amato}}, booktitle={Proceedings 2001 ICRA. IEEE International Conference on Robotics and Automation (Cat. No.01CH37164)}, title={Disassembly sequencing using a motion planning approach}, year={2001}, volume={2}, number={}, pages={1475-1480 vol.2}, doi={10.1109/ROBOT.2001.932818}} Our motion planning based approach treats the parts in the assembly as robots and operates in the composite configuration space of the parts' individual configuration spaces. Randomized techniques inspired by recent motion planning methods are used to sample configurations in this space. Since typical assemblies consist of many parts, the corresponding composite C-spaces have high dimensionality. Also, since many important configurations for the disassembly sequence will involve closely packed parts, the disassembly problem suffers from the so-called narrow passage problem. We bias the sampling by computing potential movement directions based on the geometric characteristics of configurations known to be reachable from the assembled configuration. We construct a disassembly tree which is rooted at the starting assembled configuration. Our experimental results with several non-trivial puzzle-like assemblies show the potential of this approach.

Keywords: Disassembly Planning, Motion Planning

Links : [Published] BibTex

Abstract